The FEMAG/CZ software is dedicated to the simulation of the Czochralski process. FEMAG/CZ/TMF, as an add-on module of FEMAG/CZ, provides you with the possibility to compute the effect of a Transverse Magnetic Field (TMF) on the velocity, temperature and species fields in the melt and in the crystal.

The Czochralski process simulator is used to design new hotzones and recipes that match specific business requirements, such as:

.Growth of very large diameter ingots

.Defect free silicon ingot growth

.Process yield increase

.Oxygen content control

.Carbon content decrease

.Ingot radial and axial resistivity variance decrease

.CCZ process implementation

.Design of the furnace hotzone (by a global calculation involving radiation, conduction, convection)

.Anisotropic thermal stresses in the crystal

.Point defects in the crystal

.Quasi-Steady and Time-dependent modelling

.Extensive material database

.Multiphysics simulation

.Effect of a 3D transverse magnetic field (using the FEMAG/CZ/TMF module)

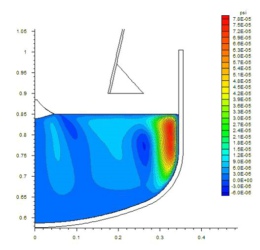

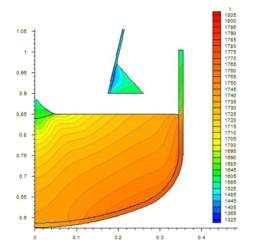

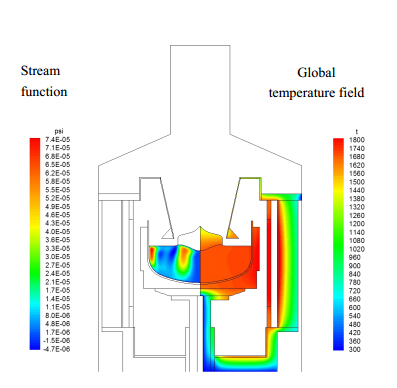

FEMAG/CZ quasi-steady simulation of the growth of a 6”diameter Silicon crystal

(Global temperature field in the furnace)

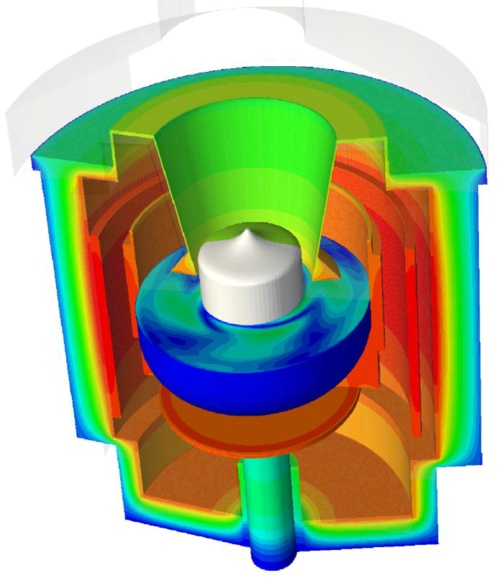

Inverse dynamic simulation of the growth of a 300 mm silicon crystal

Analysis of conical growth and shouldering stages

|

Stream function |

Global temperature field |

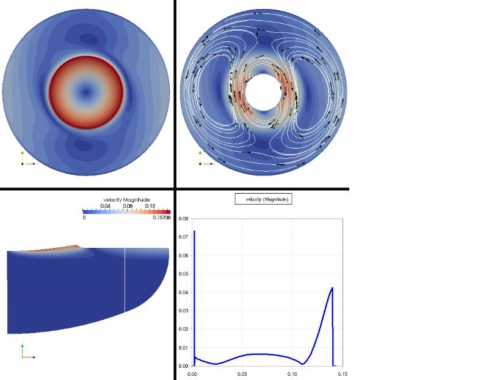

Flow and global heat transfer in a silicon Cz puller under the effect of a TMF

(quasi-steady simulation)

Growth of a 300 mm diameter Si crystal under the effect of a 0.5T TMF

Top: top view of the velocity magnitude and streamlines.

Bottom: velocity field magnitude and cross-section showing a sharp Hartmann layer along the melt-crucible interface.